- +39 030 6850942

- info@rfpintossi.it

- Via Enrico Mattei, 7 - 25050 PASSIRANO (BS)

L’azienda R.F. PINTOSSI Srl è specializzata nella produzione di attrezzature in metallo duro impiegate nei settori della trafilatura di cavi, fili, barre e tubi in metalli ferrosi e non ferrosi.

Dal 1970, anno di inizio dell’attività, la R.F. ha avviato la produzione di Shaving Dies in carburo di tungsteno (metallo duro) da impiegare nella sbarbatura di fili per saldatura in alluminio e leghe d’alluminio.

La R.F. PINTOSSI S.r.l. è specializzata nelle lavorazioni di particolari in metallo duro quali rettifica, elettroerosione a filo, tornitura, lappatura a specchio, rivestimenti PVD e CVD.

Da oltre 50 anni produciamo Shaving Dies in carburo di tungsteno, con fori compresi da ø 0,80 mm a ø 15,00 mm ed oltre. Lo Shaving Die è utilizzato nell’industria del trafilato per la sbarbatura di fili per saldatura e vergelle.

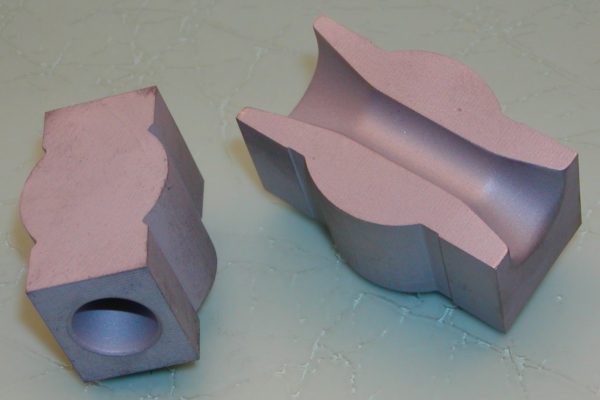

Realizziamo filiere regolabili per trafilatura, sia tradizionali con blocchetti o tasselli che particolari con spalle o sellette. La filiera regolabile è realizzata in varie dimensioni, in funzione della sezione da trafilare, con nocciolo in metallo duro.

Realizziamo mandrini in metallo duro integrale dal ø 1,20 mm al ø 12,00 mm ed oltre, in base alle specifiche richieste dal cliente. I mandrini sono impiegati nella trafilatura di tubi in rame.

Produciamo bussole guida filo e raddrizzatrici, quest’ultime impiegate per la raddrizzatura di fili o barre precedentemente trafilate in rotolo e per la raddrizzatura di tondo nervato per C.A.

Gli ugelli in metallo duro per macchine sabbiatrici e granigliatrici vengono prodotti nella versione aria e sabbia, integrale o incamiciata, impiegati come ricambi per moltissimi modelli di sabbiatrice.

L’azienda R.F. PINTOSSI Srl di Passirano, in provincia di Brescia.

Con l’ingresso nel 1978 di Pintossi Sergio nell’organico, come socio, amministratore unico e responsabile di produzione, la R.F. viene trasformata nell’attuale società R.F. PINTOSSI S.r.l., che si dedica e si specializza nella produzione di Shaving Dies in carburo di tungsteno da utilizzare nella sbarbatura di fili per saldatura di un’ampia gamma di metalli tra i quali fili d’alluminio, leghe d’alluminio, bronzo fosforoso, leghe di rame, acciaio inox, acciaio alto carbonio, ferro-nichel, fili rivestiti allo zinco ed altri metalli.

Da diversi anni la società R.F. PINTOSSI S.r.l. ha avviato un progressivo e continuo piano d’investimento in macchinari CNC ed attrezzature tecnologicamente avanzate, affiancato da un programma pianificato di manutenzioni periodiche, finalizzate al mantenimento della qualità ed affidabilità nel tempo dei propri macchinari.

La politica aziendale della R.F. PINTOSSI Srl di Passirano, in provincia di Brescia, è imperniata sul potenziamento dei macchinari, la formazione del personale, la ricerca di fornitori e materie prime di alto livello professionale e qualitativo: tutto ciò ha consentito all’azienda di elevare gli standard qualitativi dei prodotti realizzati, diventando una realtà leader sia in Italia che all’estero nella produzione di Shaving Dies.

Il personale addetto alla produzione è costantemente sottoposto a programmi di formazione interni, acquisendo un know-how che viene continuamente sviluppato ad aggiornato alle reali esigenze tecniche dell’azienda.

Questo sito utilizza i cookie per migliorare la tua esperienza di navigazione su questo sito.

Visualizza la Cookie Policy Visualizza l'Informativa Privacy

Google Maps è un servizio di visualizzazione di mappe gestito da Google Ireland Limited. Questo servizio serve ad integrare tali contenuti all’interno delle proprie pagine.

Quali dati personali vengono raccolti: Dati di utilizzo; Strumento di Tracciamento.

Luogo del trattamento: Irlanda – Privacy Policy.

Google reCAPTCHA è un servizio di protezione dallo SPAM fornito da Google Ireland Limited.

L'utilizzo del sistema reCAPTCHA è soggetto alla privacy policy secondo termini di utilizzo di Google.

Dati Personali che vengono trattati: Strumento di Tracciamento; Dati di utilizzo; cllick; risposte alle domande; eventi keypress; eventi relativi ai sensori di movimento; eventi touch; i movimenti del mouse; posizione relativa allo scorrimento.

Luogo del trattamento: Irlanda – Privacy Policy.